Preventing Turbo Engine Problems: Best Practices

Prevent turbo troubles, keep your engine roaring – follow our best practices for worry-free driving. If you’re experiencing issues with your van OR car turbo and looking to sell, simply enter your registration number to receive a free, no-obligation quote from us.

Preventing turbo engine problems is essential to ensure the longevity and optimal performance of your vehicle. One of the best practices for preventing turbo engine problems is to follow a regular maintenance schedule, including regular oil changes and air filter replacements.

Additionally, it’s important to allow the engine to cool down after driving, especially after high-speed or heavy load driving, to prevent heat-related damage to the turbocharger.

Avoiding aggressive driving, keeping the engine well-lubricated, and using high-quality fuel can also help prevent turbo engine problems. Finally, if you notice any signs of turbo engine problems, such as decreased engine performance or unusual noises, it’s important to have your vehicle inspected by a qualified mechanic as soon as possible to prevent further damage.

Understanding How Turbo Engines Work

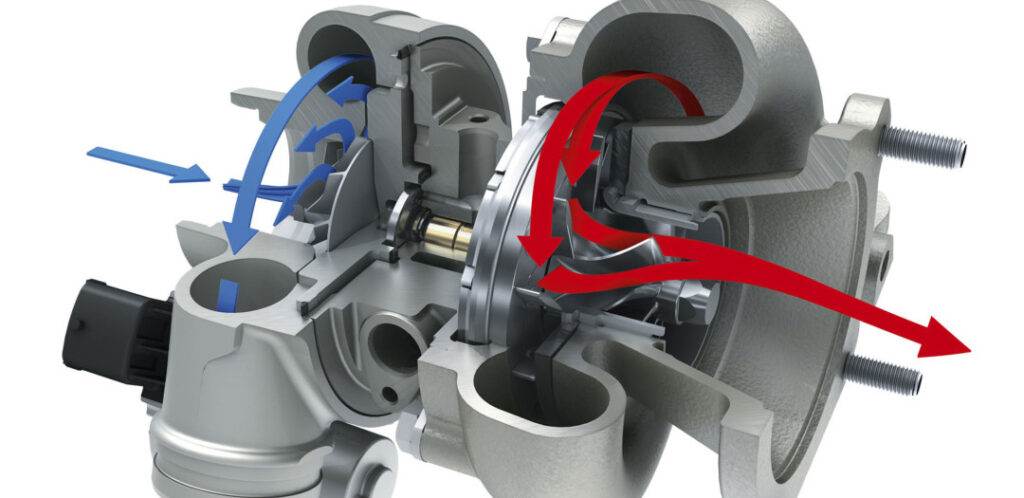

Turbo engines are designed to increase the power output of an engine by forcing more air into the combustion chamber. This is done through a turbocharger, which uses exhaust gases to spin a turbine that compresses incoming air and forces it into the engine. The result is increased horsepower and torque, allowing for faster acceleration and higher top speeds.

However, with great power comes great responsibility. Turbo engines require careful maintenance in order to operate at peak performance levels. Regular oil changes, proper warm-up and cool-down procedures, and monitoring boost levels are all critical components of keeping your turbocharged engine running smoothly.

It’s also important to choose high-quality fuel and additives that won’t clog or damage your turbocharger. And if you do experience issues such as oil leaks or coolant loss, it’s best to address them promptly before they cause further damage to your engine. By following these guidelines and consulting with a professional mechanic when necessary, you can enjoy the benefits of a powerful turbocharged engine without sacrificing reliability or longevity.

Importance of Regular Maintenance

Regular maintenance is essential for the longevity and optimal performance of any turbo engine.

Neglecting routine maintenance can lead to costly repairs, decreased fuel efficiency, and even complete engine failure. It is recommended that owners follow their vehicle manufacturer’s maintenance schedule to ensure proper upkeep.

Oil changes are an important part of regular maintenance for turbo engines. Turbochargers run at extremely high speeds and temperatures, which puts a lot of stress on the engine oil.

Over time, the oil breaks down and loses its ability to lubricate properly. Regular oil changes help prevent premature wear on vital components such as bearings and pistons.

In addition to oil changes, other crucial aspects of regular maintenance include air filter replacement, coolant flushes, spark plug replacements, and timing belt inspections/replacements (if applicable).

Following these procedures helps keep your turbocharged engine running smoothly and efficiently for years to come without encountering any major issues or breakdowns.

Choosing the Right Oil and Filter

To ensure the longevity and optimal performance of your turbo engine, it is crucial to choose the right oil and filter.

The type of oil you select should be compatible with your specific vehicle model and its requirements, such as viscosity grade, API service classification, and synthetic or conventional base oils.

Using an incorrect oil can lead to increased wear on engine parts, reduced fuel efficiency, and even engine failure.

In addition to selecting the appropriate oil type, it is equally important to choose a high-quality filter that will effectively remove contaminants from the lubrication system.

A good filter should have a high filtration efficiency rating (i.e., percentage of particles captured) and adequate capacity for holding debris without clogging or bypassing flow.

Neglecting regular filter replacement can cause restricted oil flow leading to premature wear on bearings or other components.

Consulting with a professional mechanic who specialises in turbo engines can provide valuable guidance on choosing the best combination of oil and filter for your particular driving conditions.

They may also recommend using additives or treatments that enhance performance properties such as anti-wear protection, detergency, or corrosion inhibition.

By investing in quality maintenance products for your turbocharged engine today, you can avoid costly repairs down the road while enjoying maximum power output under all operating conditions

Avoiding Overheating and Overboosting

To avoid overheating and overboosting in your turbo engine, it is important to properly monitor the temperature and boost levels.

Overheating can occur when the engine runs too hot for an extended period of time, which can cause damage to components such as gaskets and seals.

Similarly, overboosting occurs when there is too much pressure in the intake manifold, causing strain on the turbocharger and potentially leading to failure.

One way to prevent these issues is by ensuring proper airflow through the engine bay.

Make sure that air filters are clean and unobstructed, as this will allow for better circulation of cool air throughout the system. Additionally, regularly checking coolant levels and performing routine maintenance on cooling systems can help prevent overheating.

Another key factor in avoiding overheating and overboosting is using high-quality parts that are designed specifically for use with turbo engines.

This includes choosing a suitable intercooler size based on your vehicle’s power output, selecting a quality wastegate or blow-off valve, and using high-quality hoses that won’t collapse under pressure.

By following these guidelines for maintaining your turbocharged engine system properly you will be able to avoid any potential problems before they become bigger ones down the line so it’s always best practice not only keeping up with regular maintenance but also consulting with professional mechanics if you have any concerns about how your car performs or feels while driving!

Proper Warm-up and Cool-down Procedures

One of the most important things to keep in mind when operating a turbo engine is proper warm-up and cool-down procedures. This involves allowing the engine to reach its optimal operating temperature before driving and giving it time to cool down after use. Failing to do so can lead to premature wear and tear on the engine, as well as decreased performance over time.

To properly warm up your turbo engine, start by letting it idle for a few minutes before driving. This allows oil to circulate through the system and lubricate all of the necessary components. Once you begin driving, avoid rapid acceleration or high RPMs until the engine has reached its ideal temperature range. Similarly, when you’re finished using your car, give it a few minutes at idle before shutting off the ignition.

Cooling down your turbocharged vehicle is just as important as warming it up. After heavy use or extended periods of driving, allow your car’s engine to idle for several minutes before turning off the ignition. This gives coolant ample time to circulate through all parts of the system and prevent overheating or damage due to residual heat buildup.

Overall, taking care with warm-up and cool-down procedures will help ensure that your turbocharged vehicle stays in top condition for years to come. By taking these simple steps each time you drive, you’ll be able maximise performance while minimising unnecessary wear on critical components like bearings and seals – ultimately saving yourself both money and headaches down the road!

Monitoring Boost Levels and AFR

To ensure optimal performance and longevity of your turbo engine, it is crucial to monitor boost levels and air-fuel ratio (AFR). Boost levels refer to the amount of pressure generated by the turbocharger, while AFR indicates the ratio of air to fuel in the combustion chamber. Both factors are vital for achieving maximum power output without damaging the engine.

Boost gauges can be installed to measure how much pressure is being generated by the turbocharger. It’s important not to exceed recommended boost levels as this can lead to overboosting, which puts excessive strain on components such as pistons and valves. On the other hand, insufficient boost can result in decreased horsepower and torque output.

Similarly, monitoring AFR helps maintain proper combustion efficiency. Running too lean (not enough fuel) or too rich (too much fuel) can cause damage or reduce performance. An ideal AFR varies depending on several factors such as engine load and speed but generally ranges between 15-14:1 for a non-turbo and 16-15:1 for a turbo-diesel.

Regularly checking both boost levels and AFR will help identify any potential issues before they become major problems that require costly repairs. Consult with a professional mechanic if you’re unsure about how to properly monitor these parameters or need assistance with tuning upgrades for improved performance.

Avoiding Rapid Acceleration and Deceleration

Rapid acceleration and deceleration can put a lot of stress on your turbo engine, leading to premature wear and tear.

To avoid this, it’s important to accelerate and decelerate gradually, allowing the engine to adjust to changes in speed without being overloaded.

This not only helps prolong the life of your engine but also improves fuel efficiency.

Another way to avoid rapid acceleration and deceleration is by anticipating traffic flow ahead of time. By keeping a safe distance from other vehicles and maintaining a steady speed, you can reduce the need for sudden braking or accelerating.

Additionally, avoiding heavy loads or excessive speeds while driving uphill can help prevent unnecessary strain on your engine.

Lastly, it’s crucial to follow proper maintenance procedures for your vehicle. Regularly changing oil filters and checking fluid levels can ensure that everything is running smoothly under the hood.

If you notice any unusual sounds or vibrations coming from your car while driving, be sure to have it inspected by a professional mechanic as soon as possible.

By taking these steps towards responsible driving habits and routine maintenance checks, you’ll keep your turbo engine performing at its best for years to come!

Addressing Oil Leaks and Coolant Loss

When it comes to addressing oil leaks and coolant loss in turbo engines, timely action is crucial. Ignoring these issues can lead to serious engine damage and costly repairs down the line. The first step is identifying the source of the leak or loss. In some cases, a visual inspection may be enough to pinpoint the problem area, while other times diagnostic tools may be necessary.

Once you have identified where the issue lies, it’s important to address it promptly. Oil leaks can cause engine components to wear out faster than they should due to insufficient lubrication. Coolant loss can lead to overheating which can warp cylinder heads and cause head gasket failure among other things. Replacing worn-out gaskets or seals and repairing damaged parts are usually required steps for fixing these problems.

Prevention is key when it comes to avoiding oil leaks and coolant loss in turbo engines. Regular maintenance checks including inspecting hoses, belts, clamps as well as replacing fluids like oil and coolant at recommended intervals will go a long way in preventing these issues from occurring in the first place. Additionally using high-quality oils that meet manufacturer specifications along with proper installation of gaskets/seals will help keep your engine running smoothly for years without any major hiccups or breakdowns.

Remember that catching potential problems early on will save you time, money, and headaches later on down the road so don’t hesitate if you suspect something isn’t right under your hood!

Using High-Quality Fuel and Additives

One of the most important factors in maintaining a turbo engine is using high-quality fuel and additives. The quality of the fuel directly affects engine performance, as well as its longevity. It’s essential to use premium or high-octane gasoline, which contains fewer impurities and burns more efficiently than regular gas. Fuel with lower octane ratings can cause knocking or pinging in the engine, leading to damage over time.

In addition to using high-quality fuel, adding an appropriate fuel additive can help keep your turbocharged engine running smoothly. These additives can improve lubrication, reduce friction and wear on internal components, prevent corrosion and rust formation, and clean deposits from valves and injectors. However, it’s crucial to choose a reputable brand that’s compatible with your vehicle’s make and model.

When selecting fuels or additives for your turbocharged vehicle, always follow the manufacturer’s recommendations listed in the owner’s manual. Using incompatible products may void warranties or result in severe damage to the engine components. As such, it would be best if you consulted with a professional mechanic before making any changes or upgrades related to fuel selection or additive usage for optimal results without risking harm to your car’s health over time.

Consulting with a Professional Mechanic for Repairs and Upgrades

When it comes to turbo engine repairs and upgrades, consulting with a professional mechanic is always the best course of action. While there are many DIY tutorials and guides available online, attempting to fix or upgrade your engine without proper knowledge and experience can lead to costly mistakes.

A professional mechanic has the expertise needed to diagnose any issues accurately and provide effective solutions. They also have access to specialized tools that may not be readily available for home mechanics. Additionally, they can recommend upgrades that will improve performance while ensuring safety.

It’s essential to find a reputable mechanic who specializes in turbo engines. Look for someone with certifications from recognized organizations like IMI (Institute Of The Motor Industry) or those who have worked on similar models as yours. Don’t hesitate to ask for references or check online reviews before choosing a mechanic.

Overall, investing in regular maintenance by a professional mechanic will prolong the lifespan of your turbo engine while maximizing its potential performance capabilities. It’s worth taking the time and effort upfront rather than risking significant damage down the road due to improper repairs or upgrades done by an inexperienced individual.

Preventing Turbo Engine Problems: Best Practices FAQs

A turbo engine uses exhaust gases to power a turbine, which then compresses the intake air to increase its volume and density, resulting in more power.

Turbo engines operate at high temperatures and pressures, putting extra stress on components. Regular maintenance helps ensure that these components are in good condition and functioning properly.

It’s important to use oil and filters that are specifically designed for turbo engines, as they can withstand the high temperatures and pressures that these engines produce.

Overheating and overboosting can cause serious damage to a turbo engine. To avoid these issues, it’s important to monitor the engine’s temperature and boost levels, and to follow proper warm-up and cool-down procedures.

A turbo engine should be allowed to warm up before being driven aggressively, and should be allowed to cool down after driving to prevent heat buildup in the engine and turbocharger.

Boost levels and air/fuel ratios can have a significant impact on a turbo engine’s performance and longevity. By monitoring these values, you can ensure that your engine is running optimally.

Rapid acceleration and deceleration can cause unnecessary stress on a turbo engine’s components. To avoid this, it’s important to drive smoothly and avoid sudden changes in speed.

Any signs of oil leaks or coolant loss should be addressed immediately, as they can cause serious damage to your engine. Consult with a professional mechanic to diagnose and fix these issues.

Yes, using high-quality fuel and additives can help keep your engine running smoothly and prevent damage from deposits or contaminants in low-quality fuel.

It’s always a good idea to consult with a professional mechanic for any repairs or upgrades to your turbo engine, as they have the expertise and experience to ensure that the work is done properly and safely.