Wiring Loom Problems

Sell Your Van with Wiring Loom Problems to “We Buy Many Vans”: Get a Fair Deal for Your Vehicle

If you’re encountering wiring loom problems in your van and considering selling it, We Buy Many Vans is here to help. Wiring loom issues can be frustrating and lead to various electrical faults and even engine failure. Common problems include loose or damaged wires, corroded connectors, and frayed harnesses.

Regularly inspecting your vehicle’s wiring components for any damage is crucial, and addressing these issues promptly can prevent further damage. However, if you find yourself dealing with persistent wiring loom problems and decide to sell your van, We Buy Many Vans provides a convenient solution.

We understand the challenges associated with wiring issues and are experienced in purchasing vans in various conditions. With We Buy Many Vans, you can sell your van with confidence, knowing that you’ll receive a fair deal for your vehicle, regardless of its wiring loom problems. Contact us today to explore your options and make selling your van a hassle-free process.

Vehicle Wiring Loom Problems: Addressing Electrical Faults and Engine Failure

Wiring loom problems in vehicles can lead to a number of issues, including electrical faults and engine failure. Common wiring issues include loose or damaged wires, corroded connectors, and frayed harnesses. It is important to regularly inspect your vehicle’s wiring components for damage and address any issues promptly to prevent further damage.

One common cause of wiring loom failure in vans is improper installation. If the harness is not fitted correctly, it can rub against other components or become pinched, leading to wear and tear over time.

To avoid this issue, it is important to ensure that the wiring harness is properly secured and routed during installation.

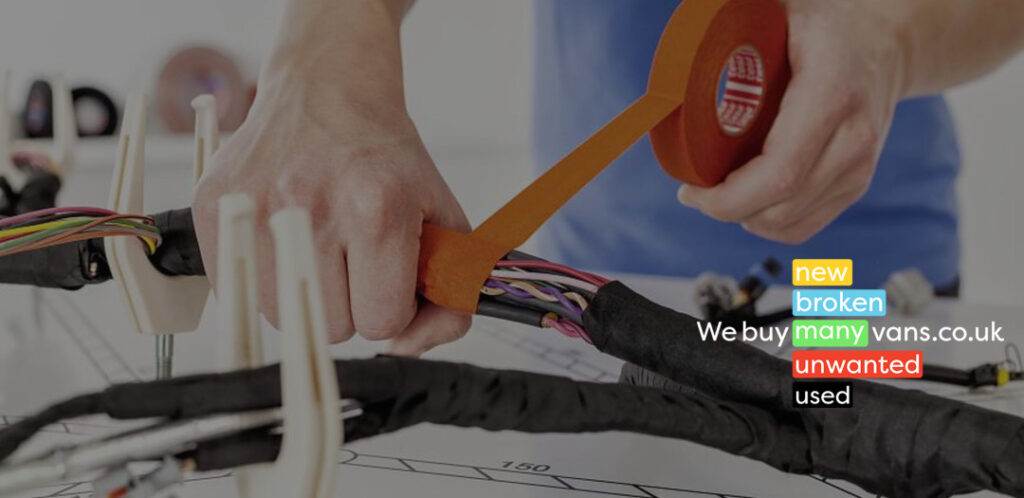

If you do experience wiring harness problems, there are several steps you can take to repair them. These may include replacing damaged wires or connectors, repairing frayed sections of the harness with heat shrink tubing or electrical tape, or replacing the entire harness if necessary. It is recommended that these repairs be performed by a qualified mechanic who has experience working with automotive electrical.

Understanding Electrical Faults in Vehicles

Common Van Faults: Electrical faults in vehicles can be caused by a variety of issues, including faulty wiring. Wiring problems are common in vans and can cause serious damage if not addressed promptly. One issue that often arises is harness problems, which occur when the wire harness becomes damaged or worn over time.

A wire harness is a series of cables that connect various electrical components within a van. These cables are responsible for transmitting signals from one component to another, allowing the vehicle to function properly. When there is an issue with the wire harness, it can lead to electrical faults and other problems.

To prevent these issues from occurring, it’s important to install wiring looms and cable protectors correctly during repairs or replacement. This will help ensure that all wires are properly secured and protected from damage caused by heat or friction. Regularly inspecting your vehicle’s wiring components for signs of wear or damage can also help prevent future failures and keep your van running smoothly without any electrical faults.

Common Wiring Issues in Vans: What You Need to Know

Automotive wiring is a complex system that connects various electrical components in a vehicle. When the wiring gets damaged, it can cause serious issues such as engine failure or electrical fires. Damaged wiring can also lead to poor performance of other mechanical systems in the van.

Proper installation of wire harnesses and wiring looms is crucial for preventing problems down the line. If not installed correctly, wires may be pinched or stretched, causing them to break or short circuit.

It’s important to ensure that all connectors are properly secured and that there are no loose connections.

One common issue with automotive wiring is when wires become corroded over time due to exposure to moisture and salt on roads during winter months. This corrosion can cause shorts between wires, leading to further damage and potentially dangerous situations if left unresolved. Regular inspection of your vehicle’s wiring components can help identify any potential issues before they become major problems.

Sell Your Van In Three Easy Steps

Hassle-Free Selling Process

01.

Get a quote

02.

Schedule a pickup

03.

Get paid

Harness Problems: Causes and Symptoms

One of the most common causes of electrical faults in vehicles is a bad wiring harness. A wiring harness is a collection of cables and connectors that are responsible for transmitting signals between various electrical components in a vehicle. If there is damage to the wiring harness, it can cause problems with electrical components such as lights, sensors, and even the engine.

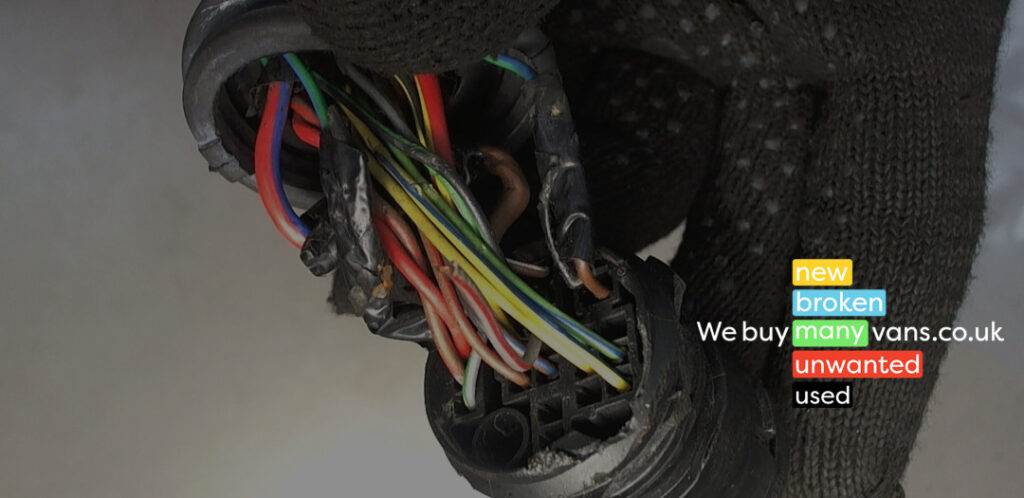

Symptoms of wiring harness problems include flickering or dimming headlights, malfunctioning dashboard gauges, and intermittent power loss. If you suspect that your vehicle has an issue with its wiring harness, it’s important to inspect it thoroughly for any signs of damage or wear. This may involve checking each individual cable and connector for fraying or corrosion.

If you do find damage to the wiring harness, you may need to replace it entirely in order to prevent further failure of electrical components in your vehicle. It’s important to note that attempting to repair a damaged cable or terminal on your own could actually make the problem worse if not done correctly. When in doubt, seek professional assistance from a qualified technician who can properly diagnose and fix any issues with your vehicle’s electrical system.

Wiring Harness Problems and How to Fix Them

Wiring harness problems are a common issue in vans nationwide. A wiring harness is a collection of wires, cables, and connectors that transmits electrical power and signals throughout the vehicle. Faulty wiring can cause various issues such as engine failure, malfunctioning lights or indicators, and even fires.

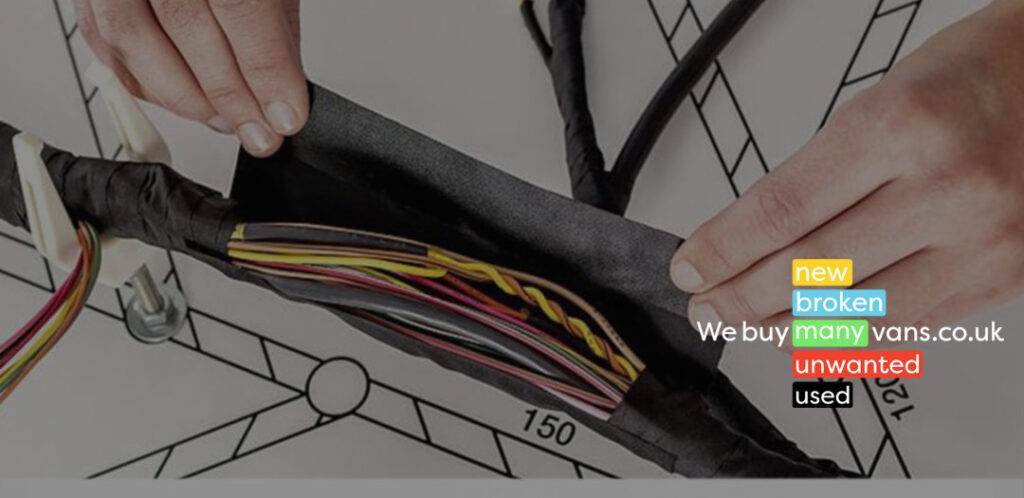

One of the most common causes of wiring harness problems is damaged insulation. This can happen due to wear and tear over time or exposure to extreme temperatures. Damaged insulation can lead to short circuits or exposed wires which can be dangerous if left untreated. To repair this issue, you may need to replace the entire wiring loom or just the affected part of it.

Another problem that often occurs with wire harnesses is broken connectors. Connectors are used to join different parts of the harness together; when they break down it results in poor connectivity between components leading to faults in your van’s electrical system. The best solution for this problem would be replacing faulty connectors with new ones.

Sometimes repairing a faulty wire harness may not be enough; you might have no other option but to replace it entirely especially if there has been significant damage caused by an accident or fire outbreak. Replacing a wire harness requires expertise since different vehicles require specific types of cable connections and fittings so ensure that you get professionals who understand how your van works well enough before proceeding with any repairs

The Importance of Proper Installation of Wiring Looms

Proper installation of wiring looms is crucial in ensuring that electrical components function properly. Failure to install the wiring harness correctly can cause problems such as short circuits, which may damage other electrical components in the vehicle. It is essential to ensure that all wiring terminals are securely fastened and insulated to prevent any potential damage.

One common issue with improper installation of a wiring loom is when wires rub against each other or against metal surfaces, causing wear and tear on the insulation. This can lead to circuit failure and ultimately result in replacement costs for damaged components. To avoid this problem, it’s important to route wires vanefully and use protective coverings where necessary.

Another important aspect of proper installation is soldering connections between wires rather than relying solely on crimped connectors. Soldering provides a more secure connection that reduces the likelihood of terminal failure due to vibration or movement within the vehicle. Additionally, using high-quality materials during installation ensures longevity and reliability of your vehicle’s electrical system.

In summary, taking vane during the installation process can help avoid common wiring loom problems such as harness issues or electrical faults caused by damage to the wiring harness itself. Properly installed looms will provide reliable performance over an extended period without requiring frequent repairs or replacements.

Proper installation of wiring looms is crucial in ensuring that electrical components function properly.

Here are some important points to keep in mind when installing a wiring loom:

- Securely fasten all wiring terminals and insulate them to prevent potential damage.

- Route wires vanefully and use protective coverings where necessary to avoid wear and tear on the insulation.

- Solder connections between wires for a more secure connection that reduces the likelihood of terminal failure due to vibration or movement within the vehicle.

- Use high-quality materials during installation for longevity and reliability of your vehicle’s electrical system.

By following these guidelines, you can ensure that your wiring loom is installed correctly, which will help prevent common problems such as short circuits, harness issues, or electrical faults caused by damage. Properly installed looms will provide reliable performance over an extended period without requiring frequent repairs or replacements.

Engine Failure Due to Electrical Problems: What to Look Out For

When it comes to automotive electrical systems, engine failure can be caused by a variety of issues. One common culprit is wiring problems, which can arise from bad wiring harnesses or poor connections within the entire wiring assembly. These issues may cause short circuits or interruptions in power flow, leading to serious damage to your vehicle’s ignition and ECU.

One potential issue that can lead to engine failure is a bad wiring harness. Over time, copper wires within the bundle may become corroded or damaged due to exposure to heat and vibration.

This can result in poor conductivity and intermittent power supply throughout the entire system. If you suspect that your vehicle has a faulty wiring harness, it’s important to get it inspected by an experienced automotive technician as soon as possible.

Another common cause of engine failure related to electrical problems is a loose plug connection within the system. This could occur at any point along the assembly – from the battery terminals all the way up through various sensors and components under your hood. A loose plug could cause intermittent loss of power or even complete shutdowns if left unchecked for too long.

It’s worth noting that some manufacturers have been known to use lower-quality materials when constructing their vehicles’ electrical systems – such as cheap plastic pipes instead of more durable metal ones for wire protection – which can contribute considerably towards early wear-and-tear on these parts over time. As such, regular inspections are crucial for catching potential issues before they turn into costly repairs down the road.

Inspecting Your Vehicle's Wiring Components for Damage

When inspecting your vehicle’s wiring components for damage, it is important to pay close attention to the crimp connections. These are often a common source of electrical problems and can lead to intermittent issues with your van’s electrical system. A technician should check that all crimps are secure and properly connected.

Another area to focus on during an inspection is the battery cables. Over time, these cables can become corroded or damaged due to exposure to moisture and other elements. If any fraying or oxidation is present, it may be necessary to rebuild or replace the cables altogether.

During installation of new wiring components, interference between wires can cause incorrect voltage readings and other problems. It’s essential that technicians follow proper wire layout procedures when installing new components in order to minimize interference and ensure correct functionality of every electrical component in your van. By customizing wire layouts based on specific needs, you can reduce the chances of future damage from occurring as well as improve overall performance over time.

Common Causes of Wiring Loom Failure in vans

Wiring loom failure in vans can arise due to a variety of reasons. One common cause is the complexity of modern vehicles, which require skilled technicians to diagnose and repair any issues. The diagnostic process involves testing individual wires for continuity, resistance, and signal variation. This requires specialised equipment and expertise that not all mechanics possess

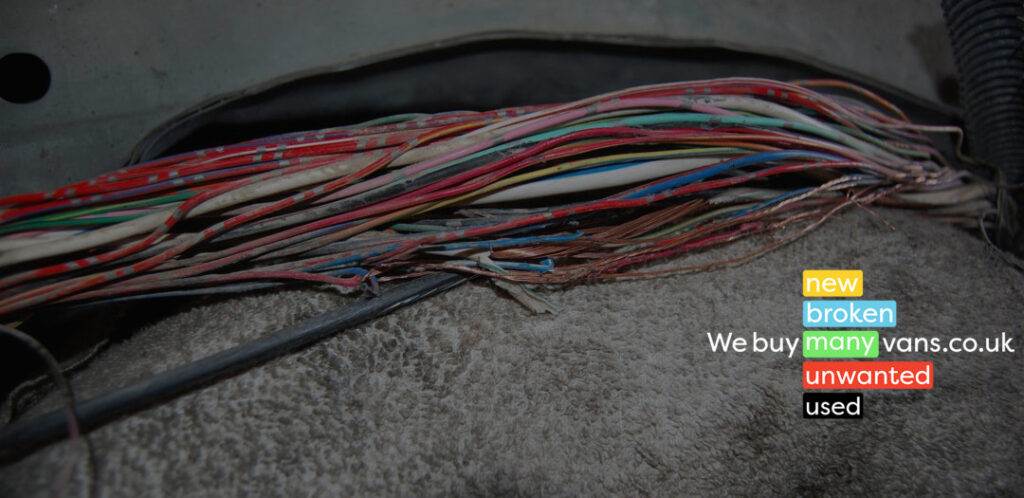

Another factor that contributes to wiring loom failure is the lifespan of the vehicle itself. Older vans are more prone to electrical faults due to wear and tear over time. Additionally, certain components such as alarms or coolant sensors may be more likely to fail than others, leading to problems with the wiring harness.

It’s important for van owners to inspect their vehicle’s wiring components regularly for damage or signs of wear. Mechanical stress on the harness from engine vibrations or accidental damage from road debris can also occur due to poor installation practices or lack of maintenance. Proper measurement and diagnostics can help identify these issues early on before they lead to complete failure of the system.

When to Replace Your van's Wiring Harness

One of the main signs that it’s time to replace your van’s wiring harness is if you notice any electrical issues. This could include dashboard lights flickering or not turning on at all, the speedometer not working correctly, or other unexpected electrical problems. It’s important to address these issues as soon as possible, as they can lead to more serious problems down the line.

Another reason to consider replacing your wiring harness is due to corrosion. Over time and with exposure to moisture and other elements under the hood, wires can become corroded and lose their ability to conduct electricity effectively.

If you’re experiencing electrical issues that are caused by corrosion, it may be necessary to replace your entire wiring harness in order to fix the problem.

If you’re having trouble finding a problem with your vehicle’s electrical system, it may be worth taking it into a main dealer for an inspection.

They’ll have specialised equipment and expertise that can help pinpoint any underlying issues that might be causing problems with your van’s electronics. And don’t worry about being limited geographically – many dealerships offer nationwide service options so you can get help no matter where you are in the country.

Van Troubleshooting Guide: Common Problems from Fuel Pumps to MOT Failures

Here’s the list of van problems in order from most common to least common:

- Fuel Pump Problems

- ECU Problems

- Fuel Injector Problems

- Turbo Engine Problems

- DPF Problems

- Wiring Loom Problems

- Oil Pressure Problems

- Differential Problems

- MOT Failure Vans

- Timing Chain Problems

- Engine Warning Light

- Gearbox Failure

Please note that the order may vary depending on various factors such as the specific van model, maintenance practices, and driving conditions. This list is a general representation of common van problems but may not reflect the exact frequency of occurrence in all cases.

Wiring Loom Problems Frequently Asked Questions

In a van, a wiring harness is a collection of electrical wires and connectors. Its purpose is to provide a structured system for transmitting electrical signals and power throughout the vehicle. Think of it as the van’s central nervous system for its electrical components. The wiring harness connects various devices like lights, sensors, switches, and control modules to the van’s power source and control systems. It keeps the electrical connections reliable and efficient while protecting them from damage or interference. Essentially, the wiring harness is essential for the van’s electrical systems to function properly.

A faulty wiring harness in a vehicle can exhibit several symptoms. Here are some common signs to look out for:

Electrical malfunctions: If you notice frequent electrical issues such as malfunctioning lights, flickering dashboard indicators, or intermittent power to certain components, it could indicate a problem with the wiring harness.

Engine misfires or stalling: A faulty wiring harness can disrupt the proper flow of electrical signals to the engine, resulting in engine misfires or even stalling. If you experience irregular engine performance or sudden engine shutdowns, the wiring harness may be a potential culprit.

Unresponsive or erratic controls: Issues with the wiring harness can lead to unresponsive or erratic behavior of various vehicle controls. This can include problems with power windows, door locks, radio, air conditioning, or other electronic features.

A burning smell or melted wires: A damaged wiring harness may emit a distinct burning smell, indicating overheating or melted wires. If you notice such odours, it is crucial to inspect the wiring harness promptly.

Visual indications of damage: Physically inspect the wiring harness for visible signs of wear and tear, such as frayed wires, exposed conductors, or damaged connectors. Corroded connectors or loose connections are also indicators of potential wiring harness issues.

If you experience any of these symptoms, it is advisable to have your vehicle inspected by a qualified mechanic who can diagnose and address the specific wiring harness problem. Timely attention and repairs can help prevent further damage and ensure the proper functioning of your vehicle’s electrical system.

Wiring harness problems can be caused by age, wear and tear, exposure to heat or moisture, and poor installation or maintenance.

Yes, a faulty wiring harness can cause engine failure if it affects the engine’s electrical system or sensors.

You can inspect your van’s wiring harness for damage by looking for frayed wires, cracked insulation, loose or corroded connections, and signs of overheating or burning.

You should replace your van’s wiring harness if it is damaged, worn out, or causing electrical problems that cannot be repaired. It may also be necessary to replace the wiring harness if you are restoring a vintage or classic van.

Sell Your Van Today to We Buy Many Vans

wiring loom problems in vehicles can have significant consequences, ranging from electrical faults to engine failure. It is essential to regularly inspect your vehicle’s wiring components for any damage and address issues promptly to prevent further complications.

Improper installation and wear and tear over time are common causes of wiring loom failure in vans.

However, if you find yourself facing persistent wiring harness problems and considering selling your van, We Buy Many Vans offers a convenient solution.

Our experienced team understands the challenges associated with wiring issues and is committed to providing a fair deal for your vehicle, regardless of its condition.

Contact We Buy Many Vans today to simplify the process of selling your van with wiring loom problems and take the next step towards a hassle-free transaction.