Turbo Engine Troubleshooting: A Comprehensive Guide

Empower yourself to keep your turbo engine running smoothly, and If you’re thinking of selling your van due to a suspected turbocharger failure, We Buy Many Vans is here to help! Enter your registration details now and get a quote!

Common Van Faults: Looking for a comprehensive guide to troubleshoot your turbo engine? Look no further! Our Turbo Engine Troubleshooting Guide empowers you with the knowledge to keep your engine running smoothly.

And, if you suspect your turbocharger has failed and you’re considering selling your van, We Buy Many Vans has got you covered!

We purchase vans of any make, model, or condition, making it hassle-free for you to sell your van. Enter your registration details now and get a quote!

Turbo engines are found in many different vehicles, including diesel vans and cars. These engines offer high performance and efficiency, but they can also experience issues from time to time.

That’s where Turbo Engine Troubleshooting: A Comprehensive Guide comes in. This guide is an essential resource for anyone who owns a diesel van or car with a turbo engine.

It covers a broad range of topics, from common problems that these engines experience to step-by-step instructions on how to fix them.

Whether you own a Volkswagen diesel van or a BMW car with a turbo engine, this guide has got you covered.

With the help of this comprehensive guide, you’ll be able to identify and fix any issues with your turbo engine, ensuring that your vehicle runs smoothly and efficiently for years to come.

How a Turbocharger Works - A Comprehensive Guide to Understanding the Basics

Turbo engines are becoming increasingly popular in the automotive industry due to their ability to produce more power and torque than naturally aspirated engines.

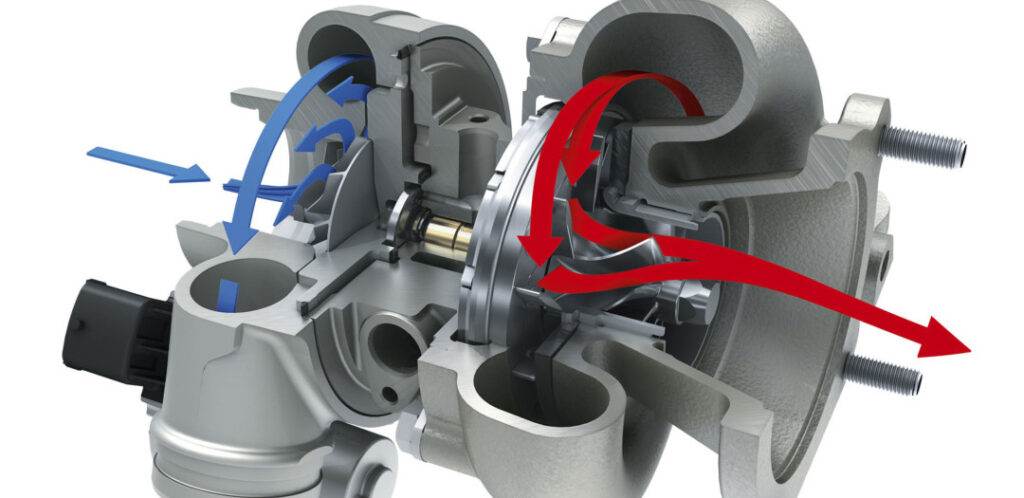

The basic principle of a turbocharger is to use exhaust gases from the engine to spin a turbine, which then compresses incoming air before it enters the engine’s combustion chambers.

This compressed air allows for more fuel to be burned, resulting in increased power output.

Turbochargers consist of several key components, including the compressor wheel, turbine wheel, and wastegate. The compressor wheel draws in air and compresses it before sending it into the engine’s intake manifold. Meanwhile, the turbine wheel is driven by exhaust gases and spins at high speeds to drive the compressor wheel. The wastegate regulates boost pressure by diverting excess exhaust gas away from the turbine when needed.

One important thing to note about turbocharged engines is that they require proper lubrication and cooling systems. Turbochargers can spin at speeds exceeding 200,000 RPMs, generating significant heat and friction that can cause damage if not properly managed. As such, regular maintenance of these systems is crucial for ensuring optimal performance and longevity of your turbocharged engine.

Common Turbo Engine Problems and Their Symptoms

Common Turbo Engine Problems: Turbo engines are known for their power and efficiency, but they can also experience common problems that affect their performance. One of the most common issues is turbo lag, which occurs when there is a delay in the turbocharger’s response time.

This can be caused by a variety of factors such as a clogged air filter or worn-out turbine blades. Symptoms include sluggish acceleration and reduced power output. Another issue that turbo engines may encounter is oil contamination.

When oil gets into the engine’s intake system, it can cause damage to critical components like the intercooler and catalytic converter. Symptoms of this problem include blue smoke from the exhaust pipe, decreased fuel economy, and rough idling.

Turbo engines may also suffer from boost pressure problems. If there is an issue with the wastegate or blow-off valve, it can lead to over-boosting or under-boosting which affects performance negatively. Indications of this problem include poor throttle response, slow acceleration and loss of power at high speeds.

Diagnosing Turbo Engine Problems Through Sound and Performance

One effective way to diagnose turbo engine problems is by listening to the sound it produces. A healthy turbocharger should produce a smooth and consistent whistling sound. If you hear any unusual noises such as rattling, grinding or hissing sounds, this could indicate a problem with the turbocharger. You may also notice a decrease in performance which can be caused by issues such as worn bearings or damaged compressor blades.

Another key indicator of turbo engine problems is poor acceleration and power output. If your vehicle struggles to accelerate quickly or loses power when climbing hills, this could be due to a failing turbocharger. Other symptoms include excessive smoke from the exhaust system, reduced fuel efficiency and increased oil consumption.

To accurately diagnose these issues through performance testing, it’s important to use specialized diagnostic tools that can measure boost pressure levels and other vital engine parameters.

By analysing these readings alongside symptom observations, mechanics can pinpoint specific areas of concern within the turbocharging system and make necessary repairs or replacements accordingly without causing further damage.

By paying attention to both sound and performance indicators, drivers can identify potential issues early on before they become more serious problems that require costly repairs or even complete replacement of their vehicle’s entire engine system.

With proper maintenance practices in place like regular oil changes and filter replacements along with professional inspections at recommended intervals will help ensure reliable operation for years to come while avoiding expensive repair bills down the road!

How to Check and Maintain Turbocharger Lubrication

Regularly checking and maintaining the lubrication of your turbocharger is crucial for its longevity and optimal performance. The first step in this process involves inspecting the oil level and quality. Low oil levels can cause damage to the bearings, while dirty or contaminated oil can lead to clogged passages and reduced efficiency.

To check the oil level, locate your vehicle’s dipstick and remove it from the tube. Wipe it clean with a rag or paper towel, reinsert it into the tube, then withdraw it again. Check that the oil level falls between the minimum and maximum marks on the dipstick. If necessary, add more oil until you reach an appropriate level.

In addition to monitoring oil levels, you should also change your turbocharger’s oil at regular intervals as recommended by your vehicle’s manufacturer. This will ensure that fresh lubricant is circulating through all parts of your engine, reducing wear-and-tear on components like bearings and shafts. Be sure to use high-quality synthetic oils designed specifically for turbocharged engines; these types of oils offer better protection against heat buildup than conventional mineral-based oils do.

Identifying and Fixing Turbocharger Boost Issues

One common issue with turbo engines is a lack of boost pressure. This can be caused by a variety of factors, including leaks in the intake system or exhaust manifold, worn out or damaged turbocharger components, or issues with the wastegate. To identify and fix these problems, it’s important to conduct a thorough inspection of all related components and systems.

Start by checking for any visible signs of damage or wear on the turbocharger itself. Look for cracks, dents, or other abnormalities that could be affecting its performance. Next, inspect the intake and exhaust systems for leaks using a smoke machine or similar diagnostic tool. If no obvious issues are found here, move on to testing the wastegate function to ensure it’s opening and closing properly.

Once you’ve identified any potential problem areas, begin troubleshooting each one individually until you find the root cause of your boost issue. This may involve replacing damaged parts like hoses or gaskets, cleaning clogged filters or pipes, adjusting wastegate settings as needed based on manufacturer specifications – whatever it takes to restore proper boost pressure! Remember that boosting too much can also cause problems so make sure not to go overboard when fixing this issue!

Troubleshooting Turbocharger Oil Leaks

One of the most common issues with turbo engines is oil leaks. These leaks can occur in various parts of the turbocharger system, such as the turbine housing or compressor housing. The symptoms of an oil leak include blue smoke coming from the exhaust and a burning smell.

To diagnose an oil leak, start by inspecting all visible components for any signs of leakage. Check for any loose bolts or damaged seals that could be causing the problem. If you cannot locate the source of the leak visually, try using a UV dye to trace it back to its origin.

Once you have identified where the oil is leaking from, you will need to fix it promptly to prevent further damage to your engine. This may involve replacing worn-out gaskets or seals, tightening loose bolts or fittings, or repairing cracks in metal components. Always use high-quality replacement parts and follow manufacturer guidelines when making repairs.

Addressing Turbocharger Overheating and Cooling System Problems

When it comes to addressing turbocharger overheating and cooling system problems, the first step is to check the coolant level. Low coolant levels can cause overheating and lead to engine damage. Make sure to top up the coolant if necessary and inspect for any leaks in the cooling system.

Another common issue that can cause turbocharger overheating is a malfunctioning thermostat. A faulty thermostat can prevent proper circulation of coolant through the engine, leading to overheating. It’s important to replace a bad thermostat as soon as possible before it causes further damage.

Lastly, consider upgrading your vehicle’s cooling system if you frequently experience turbocharger overheating issues. Upgraded radiators or intercoolers can improve heat dissipation and help keep your engine running at optimal temperatures. However, make sure any upgrades are compatible with your specific vehicle model before making any changes.

Remember that proper maintenance of your vehicle’s cooling system is essential for preventing turbocharger overheating problems in the first place. Regularly flushing and replacing coolant, checking hoses for cracks or leaks, and ensuring proper airflow through the radiator are all important steps in maintaining a healthy engine temperature.

Cleaning and Replacing Turbocharger Components

When it comes to cleaning and replacing turbocharger components, it’s important to follow the manufacturer’s instructions closely. This will ensure that you don’t damage any parts or create additional problems in the process.

To clean your turbocharger, start by removing any loose debris or dirt with compressed air. Then, use a degreaser solution and a soft-bristled brush to gently scrub away any remaining grime. Be sure to rinse thoroughly with water and let everything dry completely before reassembling.

If you need to replace any components, such as the turbine wheel or compressor wheel, make sure that you have the correct replacement parts for your specific model of turbocharger. It’s also important to carefully inspect all other related components while you have things disassembled so that you can identify and address any potential issues before they become bigger problems down the road.

Preventing Future Turbo Engine Problems Through Proper Maintenance

Regular maintenance is key to preventing future turbo engine problems. One of the most important things to do is to regularly change the oil and filter, as dirty or low oil can cause damage to the turbocharger. It’s also important to check for any leaks in the air intake system, as this can affect boost pressure and lead to poor performance.

Another crucial aspect of maintaining a turbo engine is ensuring that it stays cool. Overheating can cause serious damage, so it’s important to keep an eye on coolant levels and make sure that there are no blockages in the cooling system. Regularly checking hoses and belts for wear or cracks can also help prevent overheating issues.

Finally, paying attention to how your car sounds and feels while driving can alert you early on if there are any potential issues with your turbo engine. If you notice any unusual noises or vibrations, it’s best to have them checked out by a professional before they turn into bigger problems down the line. By following these basic maintenance tips, you’ll be able to enjoy optimal performance from your turbocharged vehicle for years to come.

Turbo Engine Troubleshooting Frequently Asked Questions

A turbo engine is an engine that uses a turbocharger to increase the amount of air that enters the engine, resulting in increased power and efficiency.

Common turbo engine problems include oil leaks, boost issues, overheating, and cooling system problems.

Turbo engine problems can be diagnosed through sound and performance. If you hear unusual noises or notice a decrease in power or acceleration, there may be an issue with your turbo engine.

To maintain your turbocharger lubrication, you should regularly check and change the oil, use high-quality oil, and avoid driving aggressively or idling for extended periods.

To identify and fix turbocharger boost issues, you should check for loose or damaged hoses, damaged wastegate, and dirty air filters. You may need to replace or clean these components to fix the issue.

To troubleshoot turbocharger oil leaks, you should check for damaged seals or gaskets, inspect the oil lines and fittings, and check the oil drain line for clogs or damage.

To prevent turbocharger overheating and cooling system problems, you should ensure proper airflow to the turbocharger, avoid driving aggressively, and regularly check and maintain your cooling system.

To clean and replace turbocharger components, you should follow the manufacturer’s instructions and use the appropriate tools and cleaning solutions. It is recommended to have a professional mechanic perform this task.

You can prevent future turbo engine problems through proper maintenance, including regular oil changes, using high-quality oil and filters, avoiding aggressive driving, and having your engine checked by a professional mechanic regularly.